Preparation and Application of Halogen-free Flame Retardant Carbon Forming Agent Piperazine Pyrophosphate

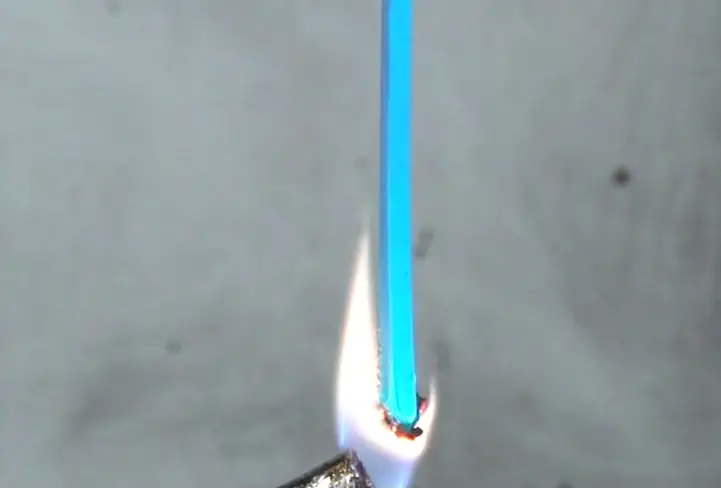

Intumescent Flame retardants (IFR) is one of the research and development hotspots in the field of halogen-free Flame retardants in recent years. IFR is generally composed of acid source (dehydrating agent), carbon source (carbon forming agent) and gas source (foaming agent). Its principle is that acid source dehydrates carbon source during material combustion.At the same time, the gas source is decomposed by heat to release non-combustible gas, forming a foam carbon layer of heat insulation and oxygen isolation on the surface of the material, so as to achieve the purpose of flame retardant.Phosphorus-nitrogen expansion flame retardants are considered as the important development direction of halogen-free flame retardants, which have the characteristics of low smoke emission, less toxic gas generation and good flame retardant effect.Typical phosphorus-nitrogen flame retardant system is composed of melamine, ammonium polyphosphate APP and pentaerythritol PER, and its flame retardant mechanism is as follows:At the initial stage of material combustion, APP is heated and decomposed into acid, which is esterified with PER and dehydrated into carbon. At the same time, melamine is heated and decomposed as a gas source, resulting in water, ammonia and other gases filling the carbon layer to expand and foam, forming a porous foamy carbon layer. The schematic diagram is shown below.

FIG. 1 Schematic diagram of flame retardancy mechanism of phosphorus-nitrogen type expansion flame retardant

FIG. 1 Schematic diagram of flame retardancy mechanism of phosphorus-nitrogen type expansion flame retardant

Appeared in recent years, many sets of acid source, carbon source, gas source in the expansion of the molecular structure of the two or even three functions in the same type of flame retardants (see figure 2), most of these flame retardants molecules containing phosphorus and nitrogen, the thermal decomposition, can produce acid dehydrating system, and can be decomposed to produce non-combustible gases make the charcoal layer swell,At the same time, it can also eliminate the molecular defects of single acid source, carbon source and gas source (such as insufficient thermal stability of single acid source APP, poor hydrolysis resistance of single gas source PER, etc.).

FIG. 2 Structure diagram of the new expansive flame retardant

There are also some limitations, such as IFR is easy to absorb moisture, compared with the traditional halogen-based flame retardant system, and influence the mechanical properties of materials.Although the above problems of IFR can be partially solved by collaborative flame retardant technology, surface modification technology, microcapsule technology, etc., the most urgent problem of IFR at present is its low hydrolysis resistance, which affects the electrical performance, weather resistance and durability of products in use and hinders the development of IFR.Therefore, the application of IFR will be further developed by using phosphorus-nitrogen expansive flame retardants with low water absorption.

Piperazine pyrophosphate is difficult to dissolve in water (its molecular structure is shown in Figure 3 below), and its molecular structure contains phosphorus and nitrogen elements, which is an organic compound with functions of acid source and gas source.The halogen-free flame retardant with piperazine pyrophosphate as the main component has excellent flame retardancy to polyolefin (PP, PE, etc.) and elastomer (TPE, EVA, TPV).

FIG. 3 Molecular structure of Piperazine pyrophosphate

Chongqing Coplyforce New Materials Co., Ltd. began to develop the industrial synthesis and production technology of piperazine pyrophosphate in 2013, and successfully applied for the invention patent "Piperazine pyrophosphate Preparation Device and Method". By the end of 2020, the annual production capacity has reached 2000 tons.Piperazine pyrophosphate produced by Copolyforce has a whiteness above 92, which can replace traditional pentaerythritol phosphate ester PEPA, CFA triazine, etc.It is not restricted by RoHS and REACH, and has completed the EU REACH registration.

Environmental protection halogen-free flame retardant

Environmental protection halogen-free flame retardant

High performance modified plastics

High performance modified plastics

Mining safety plastic products

Mining safety plastic products